David Appleyard

![322px-Eoliennes_a_Sloterdijk[1].jpg](http://www.altenergystocks.com/wp-content/uploads/2017/08/322px_Eoliennes_a_Sloterdijk_1_.jpg) Vestas Wind turbines in Sloterdijk. Photo by Aloxe. |

With annual market growth of almost 10 percent, and cumulative capacity growth of about 19 percent according to the latest figures from the Global Wind Energy Council, the wind sector continued to make robust progress in 2012. But while these figures suggest a relatively buoyant market for installations, perhaps a more accurate way to judge the health of the wind sector is to consider investment in R&D, and more specifically the products of that research, development and testing.

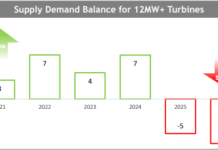

Indeed, alongside the expansion of wind markets – notably in Asia and the US, with Europe not far behind – wind technology also continued to show progress over the last year. Key trends appear to focus on larger offshore machines, new versions of existing turbines that have been upgraded and modified to suit a wider range of wind regimes and operating conditions, and a number of developments that aim to reduce installation and operations and maintenance costs.

For example, in January this year A2SEA’s new second generation vessel, Sea Installer, erected two Siemens 6-MW test turbines at DONG Energy’s demonstration site Gunfleet Sands 3.

“The turbines are getting bigger, and the future sites are further out to sea. This calls for more flexible vessels,” says Jens Frederik Hansen, CEO at A2SEA A/S. The vessel was launched from Qidong in China where it had spent two years under construction.

In autumn 2012 Hochtief also revealed a new vessel. Developed in conjunction with Areva [ARVCF], Innovation is a new heavy lift jack-up offshore installation vessel. Operating in depths of up to 65 meters, its cargo capacity is up to 8000 tons and the onboard crane can lift up to 1500 tons. Innovation was built by HGO InfraSea Solutions, a joint company of Hochtief Solutions and GeoSea.

Areva also showcased its new Single Blade Installation system (SBI) enabling the installation of blades on the hub in all positions up to 330 degrees and at wind speeds up to 12 m/s. By avoiding the need to transport assembled rotors, the system saves deck space and increases the number of machines which can be transported as a single load, Areva says. They add that the 55-ton remotely-controlled yoke was first tested in May at its prototype site in Bremerhaven, with the average time to mount or demount a blade around three hours.

Onshore, for example, Vestas [VWDRY] and SNCF Geodis are using the railways to transport blades, with up to nine 55 meter long blades transportable by train. Although railway transportation of blades is still in its early phases in Europe, Vestas says it expects to reduce costs by 10-15 percent compared to transport by road.

Larger Rotor Diameters, Higher Speeds Explored

Among the major manufacturers announcing new, larger rotor, versions of existing machines, in February Spanish player Acciona [ACXIF] revealed its new 125 meter diameter rotor for the company’s existing AW300 platform. Designed to give the 3-MW turbine superior performance at low-wind IEC Class III sites, the AW 125/3000 model stands on Acciona’s 120 meter concrete tower and has a swept area of more than 12,300 m2. Design certification for the new rotor is due for completion in 2013, with the first blades installed by the end of the year. The machine will be available for delivery in 2014 for both 50 and 60 Hz markets, Acciona says. It launched the 116 meter rotor version for IEC Class II sites in 2011.

At the recent EWEA 2013 Annual Event in Vienna, Alstom [AOMFF] also announced an upgrade of its ECO 100 3 MW platform, currently designed for medium (Class II-A) wind sites, to medium and high winds (IEC Class II-A and IS Class). The ECO 122 turbine, currently suitable for Class III sites, is also being upgraded to medium and low winds (IEC Class III-A and II B). This upgrade increases the net capacity factor to up to 48 percent for both turbines with rotor diameters of 100, 110 and 122 meters, the company says.

Meanwhile, the first wind farm featuring ECO 110 wind turbines has been inaugurated in Brittany, France, following the signing of a March 2011 contract between Alstom and Eole Generation GDF SUEZ Group for installation of 11 machines. These feature a 110 meter diameter rotor designed for Class II wind regimes and sit on a 145 meter tower.

In a related development, September 2012 saw Alstom sign a deal for the manufacture of their ECO 122 wind turbines in two wind complexes, located in the North-East of Brazil with a 600 MW annual production capacity.

Vestas also revealed a number of new machines over the past year. In the low-wind arena the wind power giant sold its first V126-3.0 MW machines in November 2012, having launched the machine at the Husum Wind fair in September. Finland’s TuuliWatti Oy is expected to see delivery of the initial batch of units in the fourth quarter of 2013.

The turbine is the latest variant of the 3 MW platform first launched in August 2010, has a rotor diameter of 126 meters to target low wind conditions (Class III) and features a structural shell blade design. The swept area has been increased by 27 percent compared with the previous model, the V112-3.0 MW, with its 112 meter rotor diameter. Featuring 55 meter-long blades, it is suitable for all three wind classes as well as offshore, Vestas says. Indeed, in June 2012 Vestas released a high-wind version of the machine. The new IEC S uses a beefed-up gearbox modified to handle the increased loads.

“The global market for high-wind turbines is diverse. In traditional and mature wind markets like the European mainland, there are not that many high-wind sites and opportunities left. However, in other markets, there are huge untapped high-wind resources and potential for high-wind specific turbines,” says Knud Winther Nielsen, senior product manager for Vestas Turbines R&D and head of the commercial development of the V112-3.0 MW.

Nielsen’s words are backed up with another new product, announced in 2012 by General Electric [GE] and the latest version of its trusty 1.5-MW platform. The 1.85-82.5 machine is destined for high wind sites in Brazil, the company says.

IEC-certified for higher wind speed sites, the new turbine offers an 8 percent increase in annual energy production at 9 meters per second over its previous model. GE says its proprietary Advanced Loads Control allows siting of the 82.5 meter rotor in more aggressive wind regimes.

New Machines, New Manufacturing

Along with new machines, new manufacturing facilities are also being developed which will produce the new generation of products.

For example, in January 2013 Alstom launched construction of two new turbine plants in

France. The Saint-Nazaire plants, expected to be commissioned in 2014, will be entirely devoted to assembling nacelles and manufacturing generators for the 6 MW Haliade 150 offshore wind turbine featuring a permanent magnet direct drive generator and a 150 meter rotor diameter. The two industrial buildings will be next to each other and will cover approximately 2.5 hectares in Montoir-de-Bretagne, within the harbor zone of Saint-Nazaire. They will be scaled for a production capacity of 100 machines per year and will take over from the temporary workshop in Saint-Nazaire where Alstom is already producing early series machines. By 2015, two other plants in Cherbourg intended for the production of blades and towers are set to be completed. The blades plant is being developed with LM Wind Power, whose 73.5 meter blades became the first 70+ meter blades to be installed when Alstom inaugurated the turbine.

LM Wind Power vice president of sales & marketing, Ian Telford, states: “Our technology enables us to design and manufacture relatively lighter glass fibre and polyester blades for the length, but above all, LM Wind Power has proven ability to handle the industrialization of these blades, which is not easy.”

Three out of the four offshore wind turbine factories will be financed through the “investissements d’avenir” (investments for the future) scheme managed by the French Environment and Energy Development Agency (ADEME).

Enercon has also announced new manufacturing capacity this year, having proceeded to series production in its new concrete tower factory in Zurndorf in Austria’s Burgenland state. At full-scale production, the plant is expected to produce up to 24 tower segments a day – a complete tower – for the E-101 3 MW turbine series. The new factory is set to produce towers for projects throughout Austria, Hungary, Romania, Croatia, Poland, and southern Germany. This latest plant followed the October 2012 start of operations at a similar, slightly smaller, facility in the province of Picardy, France.

Elsewhere, for example, China’s Sinovel [601558.SS], is reportedly in advanced discussions with Romanian heavy machinery plant Faur to jointly invest in a wind turbine production facility in Romania.

Onshore Developments

Operating exclusively onshore, Germany’s Enercon has announced a slew of developments with its new machines over the last few quarters. In mid-October the company erected the prototype of its new Class IIA 2.3 MW E-92 series atop a 97 meter precast concrete tower in Simonswolde, Ostfriesland in Northern Germany. With a rotor diameter of 92 meters, the machine is designed for lower wind sites and sits between the E-82 2.3 MW and the E-101 3 MW machines. Compared with the 82 meter machine, the E-92 can achieve up to 15 percent more yield, Enercon says. Once the power curve rating has been completed, due as REW went to press, Enercon says it will start series production.

News of the larger 2.3 MW variant followed close behind the announcement of another new machine, a 2.5 MW series with a 115 meter rotor diameter, specially designed for inland locations. Designed for average wind speeds of 7.5 meters per second and gust intensities of up to 59.5 meters per second, the E-115 is particularly suitable for less windy locations, Enercon says. Available with hub heights of 92 to 149 meters the first prototype is due to be installed this year and serial production is expected to be launched in 2014.

Nordex,[NRDXF] another wind major operating exclusively onshore, chose the recent EWEA event in Vienna to unveil its latest turbine. The fourth generation Generation Delta of its 3-MW platform has larger rotors, increased nominal output and optimized technical systems, the company says. The new range comprises turbines for strong and medium wind speeds (IEC Class 1 and 2) and includes the 3 MW N117/3000 for medium wind speeds. This is a 20 percent increase in nominal output over its predecessor. Designed for locations characterized by high wind speeds, the N100/3300 is rated at 3.3 MW, resulting in a more than 30 percent increase in nominal output. Larger rotors are being used for both platforms with the N117/3000 adding 17 meters on its predecessor, resulting in a 37 percent increase in swept area and a 10 percent boost to full load hours. Meanwhile the N100/3300 has a rotor 10 meter larger than its predecessor, increasing the swept area by 23 percent, and a taller 100 meter tower. The new machines also come with Nordex’s anti-icing system. Commercial deliveries of the new machines are set to commence at the beginning of 2014, with initial projects being installed from mid-2013. Finland’s Raahen Tuulienergia Oy will see two N117/3000 turbines installed in the port area of the Northern Finnish town of Raahe. One turbine is to be mounted on a 91 meter and the other on a 120 meter tower.

In mid-2012 Nordex also began series production of its newest variant of the 2.4 MW platform, again featuring a longer 117 meter rotor, the N117/2400 turbine.

GE, meanwhile, announced its new low wind onshore machine, the 2.5-120, at the end of January 2013. Featuring the company’s new “brilliant” technology, the turbine includes energy storage capability. With 120 meter rotor diameter, GE says the machine has a maximum hub height of 139 meters – suitable for forested regions – and produces 15 percent more power than its current 2.5 MW model.

Vic Abate, vice president of GE’s renewable energy business, said: “Analyzing tens of thousands of data points every second, the 2.5-120 integrates energy storage and advanced forecasting algorithms while communicating seamlessly with neighboring turbines, service technicians and customers.” The first prototype of the 2.5-120, optimized for Class III sites, was expected to have been installed in the Netherlands as REW goes to press. The 2.5-120 will be available at 50 Hz and 60 Hz.

Spanish firm Gamesa [GCTAF], with its range of onshore platforms from 850 kW through to 4.5 MW, unveiled both on- and offshore turbines earlier in 2012. For the onshore sector a new, longer bladed, version of its 2 MW platform has been unveiled. New blades giving a rotor diameter of 114 meters will see this 2 MW machine become available in five different rotor diameters: 80, 87, 90, 97 and 114 meters. Due to be commercially launched in the second quarter of 2014, this Class IIIA machine is designed for use at low-wind sites. The new machine has a 38 percent larger swept area than its G97-2.0 MW turbine and produces 20 percent more energy annually, Gamesa says.

Asia‘s Wind Technology Giants

Among the leading manufacturers based in Asia, Goldwind [002202.SZ] has been busy with certification of its flagship permanent magnet direct-drive platforms – it offers 1.5 MW, 2.5 MW, 3 MW machines. In February 2013, variants of both its 1.5 MW and 2.5 MW PMDD machines received ETL certification for US and Canadian markets from assessment group Intertek.

The 1.5 MW was initially certified in August 2011, the latest covers series products for low wind speed areas. In October 2012 the company announced that its ‘ultra-low’ wind 93 meter rotor diameter variant of its 1.5 MW had received domestic certification in China. This machine, the GW93/1500 was launched in April 2012 and is designed for IEC Class S, an

annual average wind speed lower than 6.5 meters per second.

During the first half of 2012, a prototype was installed in Zhucheng, Shandong province. Based on operational field data, the company says the turbine can produce close to 9 percent more power on average than the earlier model GW87/1500 series turbines (designed for IEC III class) under the same conditions.

Goldwind unveiled its 6 MW prototype in 2011 and plans to mass produce the turbines by 2014. The company assembled several of the six MW offshore wind turbines this year and plans to put at least one into operation in the first half of 2012, the company said.

Meanwhile, Japan’s Mitsubishi Heavy Industries (MHI) has unveiled a novel hydraulic drivetrain. Test operations at its Yokohama Dockyard & Machinery Works began in January 2013, the company says.

Part of a project launched in September 2012 to develop a hydraulic drivetrain for offshore turbines – supported by the New Energy and Industrial Technology Development Organization (NEDO) – MHI says it will accelerate its development of system in the 7 MW class, with installation and operation slated to begin at Hunterston, in the U.K. An onshore demonstration unit in the UK and an offshore floating wind farm project in Fukushima, Japan are slated to begin trial operations in June 2013 and August 2014, respectively, the company says. A mass-produced commercial model will be targeted for market launch in 2015. The Yokohama system is based on an existing MWT100 gear-driven wind generation system, retrofitted with the new hydraulic drivetrain.

Sinovel, another global giant, has continued with its testing program on its 2010-launched 5 MW and its 6 MW machine, launched in May 2011. Sinovel has commercially launched 1.5 MW and 3 MW and is in R&D and early production of its 5 MW and 6 MW turbines. The company is also moving to develop a 10 MW machine, with the project being listed in China’s Central budgeting last autumn. The turbine is expected to be installed as a demonstration project in Jiangsu coastal area. China’s National Development and Reform Commission awarded Sinovel a grant of RMB42 million (US$6.6 million) to accelerate commercialization of the 10 MW offshore design. Along with Sinovel both Goldwind and Guodian United Power are competing to develop a 10 MW machine after the project was deemed critical by the Chinese government last year.

Also in 2012, Sinovel teamed with Mita-Teknik to co-develop next generation control systems. Sinovel will purchase PLC hardware and the software with source code of the control systems from Mita-Teknik. The same year the company also filed a patent for a reactive voltage control system for a DFID wind generator. However, a fatal crane accident last autumn while attempting to lift a 5 MW wind turbine nacelle at the production facility in Gansu Province and continued wrangles with AMSC over intellectual property have rankled.

India’s Suzlon [SUZLON.BO] has also been active developing new versions of its existing platforms. Mid-2012 saw the company reveal its S111 low-wind turbine. This Class III 2.1 MW machine features a rotor diameter of 111 meters. The platform is now available in rotor diameters of 88, 95, 97 and 111 meters. The S111 is available with tower heights of 95 and 120 meters, and will deliver a 20-29 percent increase in annual energy production over the S97 design. The first prototype is due to be operational in late 2013 and serial production is planned to begin in 2014. Suzlon also announced improvements to IEC Class II machine, the S95 first introduced in 2011.

Outlook

It’s clear that the wind sector is benefitting from a surplus of choice when it comes to a range of turbines from the world’s manufacturers. It’s not all good news though. There have been closures and go-slows, with Nordex cutting staff at its Dongying blade manufacturing site in China and Sinovel ordering a go-slow on production, for example. In the U.S., Vestas laid off workers at blade factories in Colorado last year, with the company reducing its workforce in the U.S. and Canada by about 20 percent in 2012.

Nonetheless, while the ebb and flow of global business will inevitably see production capacity ramp up and decline in response to demand, at its core the wind business represents a technology and innovation business. We see evidence for this beyond the new variants and new machines. For instance, in the last year Gamesa raised €260 million from the European Investment Bank for its R&D+I investment program, focused on developing its two new wind turbines. Meanwhile Enercon launched the construction of its new R&D Centre, the Wobben Research & Development (WRD) facilities, scheduled to be operational by mid-2013. Investment in R&D pushes the economic boundaries of wind power today and given evidence, that boundary is being pushed hard.

David Appleyard is Chief Editor of Renewable Energy World. He also currently holds the position of Chief Editor for sister publication Hydro Review Worldwide. A journalist and photographer, he graduated with a degree in Applied Environmental Science.

This article was first published on RenewableEnergyWorld.com, and is reprinted with permission.

David,

Great recap.