One potentially huge contributor to decarbonization of the economy could come from dramatic efficiency gains obtainable from digitally improving the power quality of electricity, as it is being generated, transmitted & being consumed. The enabling technology is emerging from developments in computing that is associated with the Internet of Things (IOT).

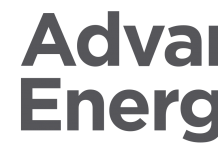

DOE estimates indicate that approximately 38.2 quads of electricity are produced, from all sources, but that 25.3 quads, or 66.2% is deemed “Rejected Energy”, so only 33.8% of generated electricity is actually being used. Within that 66% a distinction is recognized between “Losses” & “Waste”:

- Loss is non-recoverable, I2R losses that would occur unavoidably in a theoretically ideal electrical network.

- Waste is recoverable, because it is due to unsynchronized power & non intelligent distribution of electricity, which is potentially correctable.

The DOE does not quantify the proportions, but independently it has been estimated that as much as 50% of the Rejected Energy may be recoverable, so 50% of the 66%, perhaps 30-35% of the total generated, may be accessible to mitigation by waste-reducing technology. This constitutes a market of billions of dollars in potential savings which is being addressed by a huge Power Quality market competing to provide products & methodologies to mitigate waste due to distortions and inefficiencies. Despite these advancements and the scale of the industry offering solutions, data that would quantify the amount of waste actually mitigated is hard to find, perhaps because measurement and verification methods are inadequate, non-digital.

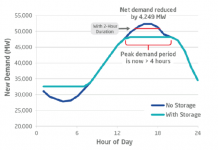

Suffice to say, a fully optimized Grid with zero waste that was able to add another 30-35% to the available 33%, would nearly double the capacity of available electricity. This might have the effect of flattening demand forecasts, or even render some existing capacity redundant. And if adoption of optimization solutions was rapid enough, sufficiently large curtailment could result in financial stranding of surplus generating assets, which in turn could impact the public conversation about use of fossil fuels for power generation, accelerate wind down of coal plants and increase awards to battery peaking over gas peakers.

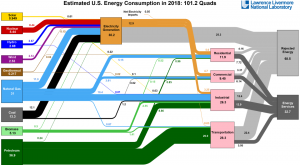

The main focus of Digitial Electrification is reduction in the thermal waste produced by inefficiencies in power quality due to various distortions in the shape of the sinusoidal wave form.

What Digital Electrification is NOT

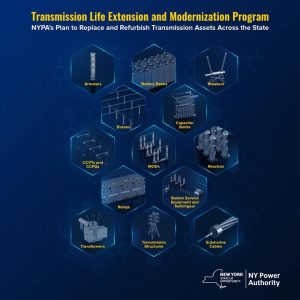

Digital Electrification is distinguishable from the “Digitization & Digitalization” broadly associated with “demand response” capabilities, and the many products and sub-disciplines instrumental to the goal of transitioning to a “smart grid”. The breadth of this far-reaching industry is captured in this infographic by ABB & Zpryme, showing 3 stages, dozens of goals in process, and a long list of topics & acronyms, the most familiar perhaps include:

- Smart meters (AMI – advanced metering infrastructure) to automate end user peak demand reductions, reduce inefficiencies and pass along cost savings.

- Demand Response Management Systems (DRMS), to coordinate load shifting

- Distributed Response Management Systems (DERMS), support integration of Distributed Energy Resources (DERs) & integration of intermittent generation from renewables, solar, wind & storage to support energy arbitrage, aggregation of batteries on site & in vehicles (V2G) into Virtual Power Plants (VPPs), and implement “non-wires alternatives” (NWAs).

- Supervisory Control & Data Acquisition (SCADA), big data management of circuit balancing,

- Outage Management Systems (OMS)

Digital Electrification is based on Software Defined Electricity (SDE)

3DFS is a small start up in North Carolina dedicated to development of SDE, which last received national level press coverage in a profile published in 2016 by Vox. Chris Doerfler, CEO of 3DFS, contends that waste due to poor power quality is fixable with 3DFS technology.

SDE is actually a term in use by other firms, such as vendors CUI & VPS, which essentially offer high end demand side management, reducing consumption by controlling equipment assets with equipment and sensors distributed throughout the equipment, managed through APIs, and can achieve some efficiencies in usage through peak shaving.

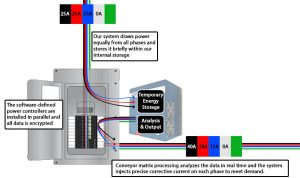

3DFS is different from these companies because its technology manages the way electricity moves through a power grid, not where it moves. 3DFS instead is installed non-intrusively in parallel directly to the electrical network panel, and is able to monitor & correct the flow of electricity itself, recognizing any non-sinusoidal waveform, line impedance or reactive power from unbalanced phases, that is producing waste heat.

Electricity is currently not precisely measured, rather, existing technologies use estimations calculated using Root Mean Square (RMS). RMS values are averages of electrical parameters based on less than 1% of real values. Most “smart” meters are inexpensive & low fidelity because they do not have digital processors. RMS sampling acquire 6000 values every second, 100 data points per sinewave at 60hz, or roughly one data point every .17 milliseconds which leaves as much as 99% unsampled. This data quality is not high enough to be usable for correcting distortions. Based only on this imprecise data, existing technologies typically compensate using transformers, capacitors and power switching technology. But in order to correct electricity more efficiently, continuous subcycle information is needed.

3DFS data acquisition oversamples the electricity, acquiring 26 separate electrical parameters (current, voltage, phase angle, power factor, harmonics, reactive power) at MHz frequencies and 24 bit resolution, 8192 times per cycle. This provides an exact digital replica of the analog signal within a few nanoseconds, with no errors, no rounding, and zero noise, rendering RMS values obsolete, because it acquires the data nearly 50,000 times faster than any technology that relies on RMS values.

Software-Defined Electricity is an application of Task Oriented Optimal Computing (“T2C”) which is “model-based” computing that creates a layer of metadata from a feedback loop on the operation of the controller. T2C is embedded onto simple ARM processors (Advanced RISC Machines). These ARM processors are capable of handling high volume data, by using a) high end FPGAs (Field Programmable Gate Arrays) and b) Reduced Instruction Set Computing (RISC).

Terabytes of data are generated, but as the data feeds into load disaggregation models and is processed by analytic & predictive algorithms, 99% of the foundational layer of operational data used in the controller is constantly erased and written over every few microseconds without ever being transmitted outside the device, providing the ultimate form of data security. The 1% fraction of data that is not erased is used to maintain the working model of the device operation and to display reporting information. And although operating with supercomputer capacity, it has very low power requirements, only 120 watts.

Doerfler credits these data processing developments to the creative efforts of two scientists on staff, Vladislav Oleynik and Gennadiy Albul. The model based matrix computing concepts are not patentable IP, since already in the public domain, but proprietary applications are protected as trade secrets. 3DFS also controls an innovation in material science for proprietary ultra-high frequency sensors.

Power Quality Rating (PQR)

Power Quality Rating (PQR)

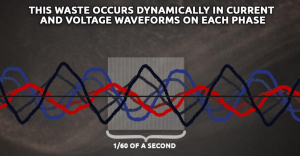

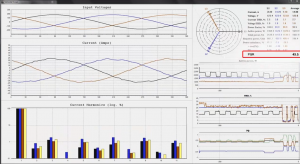

This real time layer of electricity informatics for modeling both the supply side power and the load side demand, can be represented in a single metric – the Power Quality Rating, which in turn provides the basis for the correction technology. Traditional power quality metrics focus mostly on harmonics and power factor. However, an imbalance across phases can induce neutral currents on the load side and cause eddy currents in the upstream transformer on the utility side, both of which also contribute to direct losses, and should be factored into power quality calculations. The 3DFS version of Power Quality Rating combines power factor, harmonics & phase balance, and hence is able to more accurately analyze how much electrical energy waste is occurring in the moment.

Power Quality Correction

The 3DFS Power Controller models power quality in nanoseconds, and calculates the precise microsecond to either inject or extract microamps to optimize the circuit components restore the waveform close to ideal, effectively achieving “noise canceling”.

The Power Controller contains a parallel device, the Flash Energy Storage System (FESS), which contains capacitive and inductive components that are directly controlled by the TOOC computing. This supplies the real time capacitance and inductance needs with microamp charges and discharges at the microsecond level, which corrects the distortions in each aspect, power factor, harmonics & phase imbalance, resulting in digitally synchronized electricity, automatic impedance matching for the entire panel. It also calculates the overall electrical load balance of the entire network and adjusts accordingly, eliminating upstream neutral and ground currents.

3DFS has engineered the system into several products for targeted applications, the main product is called VectorQ2, designed to be attached in parallel non-intrusively to any power network, from a small commercial building or microgrid to a massive utility load circuit.

When the VectorQ2 is installed, it profiles each downstream load attached to the panel down to the level of each individual circuit board component, and continues to improve the resolution of that profile over time because of artificial intelligence algorithms, as it recognizes in each component the variances that exist even within manufacturing tolerances. This real-time visibility into each device enables not only improved load performances, but can also detect changes from faults or degradation, reducing maintenance costs. It can also identify when a device may have been hacked & can correct the problem, offering cybersecurity protection as a bonus.

Operational effects can be monitored as shown in this walk through of the system dashboard, which identifies the derangement of the current wave forms, the phase angles, harmonics, and the PQR, before & after correction.

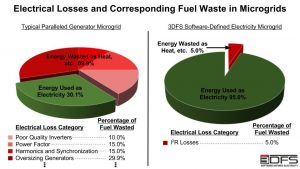

If an electrical network starting with a PQR of 28%, meaning it is only utilizing 28% of the electrical power and wasting the remaining 72% to heat or vibration, were to add a 3DFS Controller, the network would achieve a PQR of 94%, reducing losses to only 6%. Similarly, if a 3DFS controller were paired with a generator with a starting PQR of 31% & losses of 69%, it would operate after operate with a PQR of 97%, dramatically increasing the output of the generator by reducing the heat waste to 3%, with fuel savings of up to 25%.

Data Centers

Data centers are big power consumers that make substantial investments to mitigate risks associated with poor power quality, so they are an ideal test case to conduct a Proof of Concept commercial application. One such assessment was conducted by Freudenberg IT (FIT), a global company with $5B in revenues, with a US HQ in NC that hosts critical software services for Fortune 500 clients. The results were described by Michael Heuberger (CEO of the US division) as “almost unbelievable”, observing immediate 20% reductions in power consumption and 20F drop in server temperature, as the PQR went from less than 30% up to 96%. He projected substantial savings in power usage of 20-30%, reduced air conditioning costs, and ability to use smaller copper cables. But even more significant savings would come from avoiding data losses due to power network disturbances from start up of generators and air conditioners, and servers rebooting, less downtime & lower labor costs for maintenance, and less expense for mitigation of cybersecurity risks. The VectorQ2 system sized to meet the needs of FIT was $100K in 2016, with a 7yr payback, but prices have been dropping. Doerfler enumerated benefits that would factor into Return on Investment for data centers.

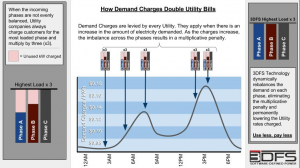

Demand Charges

Utilities add penalties on users with spikes in utilization. When one phase is high, the demand charge imposes a 3x penalty on the highest phase being metered. By rectifying phase imbalances, equalizing all 3 phases so that loads are not excessively drawn against one phase, demand charges can be substantially reduced, and the resulting savings can be significant over time. Further, there are load spikes upon motor start ups without protection.

Microgrids

One of the purposes of microgrids is to be able to manage power self-sufficiently, with generators, solar panels, microhydro, & batteries, and to have ability to operate “behind the meter” disconnected or “islanded” from the grid, but still have access when necessary, for backup power supply and to be able to export surplus power back into the grid. At the critical moment of reconnection, the utilities require that the power quality of the microgrid meet stringent conditions because of the risk of systemic disturbances in power quality when grid connection is established. Consequently, microgrid developers design in redundancies in corrective mechanisms, capacitor banks, voltage regulators, and tend to overbuild. However, with the VectorQ2 system in place, the interconnection dynamics result in perfectly seamless integration, which means that microgrid managers can save costs by reducing these redundancies in oversizing. Another risk when phases are imbalanced that can affect microgrids especially, is that current can spill into the neutral wires, which increases fire risk, and risks to workers touching unexpectedly activated wires. So microgrid networks with 3DFS power correction will reduce or eliminate that risk for fire, worker injury and associated increased liability risks. As the 3DFS technology is increasingly recognized as solving these problems for microgrids, use of microgrids will step up in the sectors they are already being utilized, hospitals, campuses, nautical electrical systems for the Navy, and other sectors will begin to open up.

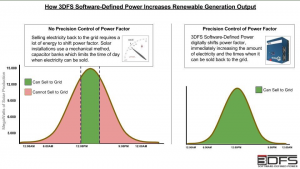

Utility scale Solar distributed generation

Another major grid-edge application is to improve the functioning of inverters used in solar power, to convert DC power from the panels into AC power, that can be synced to the grid that meet specs for low levels of harmonic distortion. Currently PV inverters are achieving 98% efficiencies, and the goal to improve to 99% is driven as much by the desire to reduce cooling requirements as the goal of higher power yield. The 3DFS solution not only can achieve those improvements, as with microgirds, it substantially normalizes the power quality to be able to sync to the grid with near zero perturbations, far more efficiently than currently available technology. Additionally, the more precise control of power factor with the 3DFS controller rather than with capacitor banks, expands the available time that a solar system can export power to the grid.

Most importantly, since grid interconnection is perhaps the single most daunting hurdle to accelerating utility scale solar market penetration to achieve displacement of fossil fuels power generation, the 3DFS technology solution could be the key to eliminating a principal barrier to integrating renewables at the pace needed to meet climate challenges.

SAM Controllers for end use devices

End use equipment, including pumps for air compressors, water wells, irrigation & sewage, bilge, conveyors, liquid sensors, and any other systems using Programmable Logic Controllers (PLC), can be converted by embedding 3DFS digital controllers with all the same data acquisition Task Oriented Optimal Computing & correction capabilities of the VectorQ2 unit. Air compressors, for example, in addition to efficiency gains from power quality correction, can benefit by improving function during startup when the motor is loaded, causing the current draw to be much higher, & when draining condensate from the expansion tank and releasing too much air, causing the tank to get repressurized more frequently. SAM Controllers will always soft start the motor unloaded, allowing it to warm up before loading it with the pump, which significantly reduces the amount of current required to startup. Additionally, the Compressor Controller constantly calculates the precise amount of condensate being created during compression & drains the condensate using the exact amount of air required, reducing the number of times the pump must repressurize the expansion tank. These two intelligent operations will result in substantial savings, both in energy consumption and maintenance costs. The ultimate vision is to get the technology small enough to fit on a chip. Each electronic device would have an SDE chip (like its wifi chip) that perfectly synchronizes electricity for its circuit board — a kind of “Intel Inside” for power quality.

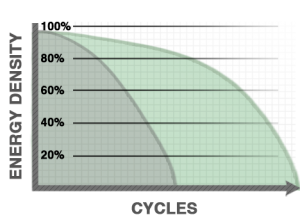

Software Defined Battery Management System

By digitizing the electricity, oversampling & disaggregation of that data, SDE can build a working chemical model for each battery  “so accurate, we can see dendrites growing and can react with corrective action in microseconds.” SDE can efficiently charge and discharge batteries at ideal maximums and minimums, which increases the number of charge cycles by 2-3x. It can digitally withdraw a battery from service and run restorative charging/discharging cycles and automatically reinsert without service disruption.

“so accurate, we can see dendrites growing and can react with corrective action in microseconds.” SDE can efficiently charge and discharge batteries at ideal maximums and minimums, which increases the number of charge cycles by 2-3x. It can digitally withdraw a battery from service and run restorative charging/discharging cycles and automatically reinsert without service disruption.

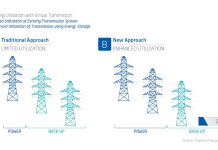

Utility scale applications

The elephant in the room is the question of how much it would cost to implement for utility scale grid applications, for primary turbine generating facilities, and for balancing long distance transmission lines, at major substation transformers and large user transformers. 3DFS literature indicates that SDE can benefit transformers, reducing losses for stepping power up or down to less than 2%. It indicates that the technology can be adapted all the way up the supply chain, to service secondary substations and power plants, and is scalable from 120V up to 25kV.

The visionary goal in the premise of this article, that as much as 50% of the energy wasted to power quality inefficiencies could be avoided, will require that the solution be adopted at all stages of the value chain, at generating facilities, along all nodes of the transmission system, and in end use networks and devices. Commercial utility scale generators, no matter what the fuel source, will need to acquire & install these units, as either voluntary or mandated capex. Market driven acceptance will dominate if the anticipated cost savings become well documented. If the power savings is widely confirmed but cost recovery remains unappetizing, then regulated utilities would need to be compelled by their governing utility commissions to integrate these units at all substations, etc. Licensing fabrication of end use applications with 3DFS units embedded would also accelerate penetration. It will take years of promoting the benefits of this technology to expect to witness a complete transition, with all the forecasted benefits.

The ultimate goal is for electricity derived from fossil fuels to have a feasible exit from our energy portfolio. With the assumptions scaled, the conserved energy from SDE corrected electricity would actually eclipse all other renewables in volume of power produced in the U.S. within 20 years. It would represent the single largest defacto “source” of renewable energy, as avoided generation from conservation, or to use a phrase by Amory Lovins, founder of the Rocky Mountain Institute – power from “negawatts”.

Two other major trends could recognize synergies from 3DFS Digital Electrification:

- Decentralization of grid architecture, which is needed to unleash the proliferation of more distributed generation, microgrids, & other “grid edge” technology, at a much quicker rate of adoption. Technical solutions have been articulated to fix the current bottleneck of structural disincentives for utilities, as outlined in Democratizing the Grid, which references a study published in IEEE & an article by David Roberts at Vox. The current crisis is an opportunity (per Goodrich Sonsini), and is being seized as seen in bill passed in WA.

- Upgrading long distance transmission to High-voltage Direct Current to enable long range transmission of renewables from remote territory to urban centers, which will also reduce transmission losses, as discussed in Future of electricity transmission is HVDC,

Negawatts crypto

A couple of economists from Columbia University proposed a Network Capital theory of currency as a protocol, with currency value being predicated on network participation. They evolved the concept into a cryptocurrency called SolarCoin based on Proof of Stake that is given away to solar developers. It is actively traded under ticker SLR. Although market cap is small and trading volume very thin, it nevertheless has grown by substantial percentages within the two years since inception. The value proposition to solar project developers is a) that it costs them nothing and they will accumulate annual grants based on kWh of power generated for the duration the system is in operation; and b) as the network expands, the value also increases, in what is expected to be an actual balance sheet asset, adding market value to the operating asset for subsequent disposition or refinancing.

A variant that might be proposed to apply to conserved power rather than generated power, a crypto that could perhaps be called NegawattsCoin (NGW), and attach it as a grant to every purchaser of a 3DFS product, whether stand alone VectorQ2 or embedded SAM controllers, tied to power saved. The idea is in conceptual stages, but could conceivably add an inducement to adoption.

Conclusion

It appears that this technology is well beyond the point of technical validation, there have been numerous proof of concept 3rd party trials, and there is a very significant field application test being conducted by a lab specializing in microgrid sector system analysis, which will be producing a comprehensive report that is expected to confirm dramatic enhancement of interconnect integration. The challenge for this company is to evolve a path of expansion as quickly as is feasible without getting ahead of itself, and to distinguish its technology from competitors that may have some similar developments, such as GridBridge. It needs to build alliances for distribution networks, licensing partnerships, apply & be awarded contracts for public RFPs, and find the answer to the riddle of acceptance by public utilities, and rural electric coops, and weigh the benefits of merging with larger entities with more resources. Potentially its best markets in the near term will be microgrid EPC design engineering firms and community solar developers. The possibilities are endless but the urgency to make a difference could not be overstated.