John Lounsbury

With the furor over the potential for hybrid, plug-in hybrid and all-electric cars recently, one might think the hydrogen car was dead. Nothing could be further from the truth. Feasibility at an affordable price appears to be established and market availability of hydrogen powered cars may come sooner than you think.

Many issues remain to be addressed and this article will try to cover them. The problems to be overcome are not insurmountable, but are also not trivial. These problems include the economics of hydrogen production, transportation, distribution and storage systems, as well as safety issues for cars involved in collisions.

Alan Ohnsman, writing for Bloomberg, reports that GM (MTLQQ), Toyota (TM), Daimler AG (DAI) and other car makers want to start supplying car fueled by hydrogen as soon as six years from now. Quoting from the article:

“The advances that have been made by the automobile manufacturers are remarkable,” said Scott Samuelsen, director of the National Fuel Cell Research Center at the University of California, Irvine. “Infrastructure is the Achilles’ heel.”

The fuel cell center opened in 1998 and is funded mainly by the U.S. government and California Energy Commission. It has also received grants from Toyota and Royal Dutch Shell Plc’s hydrogen unit, said Kathy Haq, a spokeswoman for the center.”

Here is a picture of a Royal Dutch Shell (RDS-B) hydrogen fueling station in New York City, discussed in a Seeking Alpha Instablog in August

According to the Ohnsman article, the economic factors are starting to line up for hydrogen. He quotes a Toyota objective of a $3,600 price premium for a hydrogen fuel cell powered car. This compares to the current price premium for the Synergy Hybrid Drive system from Toyota, currently averaging around $4,000 for the Camry. This is quite a change from the $1,000,000 price tag estimated to build one of these vehicles just a few years ago.

Advantages of Hydrogen Fuel Cells over Batteries

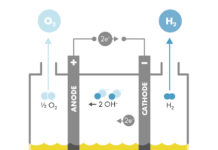

To understand the significance of this topic, one must first recognize how the hydrogen fuel cell powers a vehicle. Hydrogen fuel cell powered vehicles are electric vehicles. Hydrogen is not burned like a hydrocarbon fuel. Hydrocarbons are storage media for thermal energy which is released for power in an internal combustion engine. The hydrogen fuel cell is a storage medium for electrical energy, which is released when hydrogen and oxygen are combined electrochemically to release electricity. The hydrogen fuel cell is conceptually a battery, providing electricity to power an electric car. Unlike other battery powered cars, the fuel cell uses an onboard source of energy (hydrogen “fuel”) to generate electricity and does not have to stop to be recharged. The advantage of hydrogen powered cars is basically a long driving range, requiring only a fuel refill like internal combustion cars do today.

The hydrogen powered car has advantages for long trips. For daily commutes under 100 miles round trip, the operational convenience of battery and fuel cell energy storage is similar. In fact, it could be argued that the convenience of plugging in within your own garage to recharge batteries is more convenient than finding a refueling station every few hundred miles. The ultimate decision for most commuters will be which power source is cheaper.

Fuel Cost

The most convenient metric to compare fuel costs across the ICE (internal combustion engine) – electric drive interface is the fuel cost per mile. Miles per gallon (mpg) becomes an awkward measurement. Consumers will be required to start thinking in cost per mile terms, because that will become the comparative price on the new car sticker. According to http://www.costpermile.org/, the electricity “fuel” cost per mile (CPM) for electric cars will be between $0.01 and $0.05. Currently electric utility charges per kWh (kilowatt hour) run between $0.10 an $0.15 in most of the U.S., so most of this large range in costs must be associated with the difference in engineering technology and size of the vehicle.

Since I like a larger car, my example will compare to a mid-size Toyota Camry Hybrid. The assumed cpm for an equivalent electric car will be $0.05. (Disclosure: I own a Camry hybrid.) At $2.50 per gallon (near the national average price as this is written), the Camry has a cpm of $0.07 at $3.50 per gallon, the cpm is $0.10. I have used 35 mpg for the Camry hybrid. This is 3% higher than the sticker and 10% lower than my actual experience.

For the standard Camry the cpm would be $0.08 and $0.11 (highway and city, respectively) at $2.50 per gallon and $0.11 and $0.16 at $3.50 per gallon. The sticker mileage numbers have been used for the ICE Camry. These fuel costs are summarized in the following table.

|

Estimated Cost per Mile (CPM) |

||||

|

Car |

Gas at $2.50 per gallon |

Gas at $3.50 per gallon |

||

|

Design |

City |

Highway |

City |

Highway |

|

Camry ICE |

$0.11 |

$0.08 |

$0.16 |

$0.11 |

|

Camry Hybrid |

$0.07 |

$0.07 |

$0.10 |

$0.10 |

|

“Camry”* Electric |

$0.05 |

$0.05 |

$0.05 |

$0.05 |

|

*An electric car equivalent to the Toyota Camry. |

||||

|

Electricity cost assumption for Camry equivalent is $0.05 cpm |

||||

If the range available with an all electric car is sufficient, then customer acceptance will require that purchase costs (and maintenance costs, which will be ignored here) to be such that the purchase price difference is more than recovered in, say, 100,000 miles. The cost savings for city driving at $2.50 per gallon for gasoline is $6,000 per 100,000 miles of driving, compared to an ICE car. At $3.50 per gallon the cost savings would be $11,000. If two cars are available for our commuter and the electric car purchase cost difference is less than $5,000 more, there will be a big market. If the purchase price is $12,000 more, the market will be limited until the cost of gasoline exceeds $3.50-$4.00 per gallon.

In an August 6 press release, Toyota reported the results of a one-time driving test comparing a Toyota Hybrid Highlander with a new 4th generation fuel cell equipped Highlander Hybrid. In that test, the cpm for the production hybrid was more than double the cost for the fuel cell equipped model. I am taking this test result with a grain of salt because it was a one time test.

The remaining comparison to be made is hydrogen fuel cells to plug-in electric vehicles. Hydrogen requires power for production by electrolysis of water. If the same power is used that is available at the residential power plug, all the added costs of handling, storing, transporting and distributing hydrogen are added to the costs that one has at his own power plug. Hydrogen is very uncompetitive on a cost basis with other sources of power in this scenario. If the cost of gasoline goes much higher than the $3.50 we have in our examples, then hydrogen might compete there. But hydrogen can never compete with electricity for local driving (right now under 100 miles per day) if the same electricity source is used for both battery recharging and fuel cell operation.

Never forget that a hydrogen fuel cell is nothing more than another form of battery, wherein a chemical reaction produces electrical current. A hydrogen fuel cell car is an electric car.

Can Hydrogen be Produced with Cheap Power?

Do sources of electrical power exist that are cheaper than what we produce (or can produce in the future) for domestic consumption? The short answer is: Yes. (Well, maybe.)

One possible source of cheap electrical energy is from ocean currents that have a large temperature differential between the surface currents and those at depths of 1000 feet or so. This process is called OTEC, Ocean Thermal Energy Conversion.

The above graphic, from The World Energy Council 2007 Survey of World Energy Resources, shows that most of the areas with the largest thermal differentials occur in areas that are too far from populated shorelines to make feasible electricity generation for transmission into a power grid. Temperature differentials of 20o C or more are necessary for efficient power generation.

The cost estimates for power from OTEC are somewhat problematic. The World Energy Council estimates that a single 10MW demonstration plant would produce electricity at a cost somewhere between $0.14 and $0.21 per kWh, depending on factors such as recovery of potable water and marketable chemicals such as ammonia and various salts. The existence of carbon tax credits could lower the costs further by as much as $0.03.

It is only with the building of multiple plants of the same design that costs may come down below $0.12, the reference cost for existing electricity generation. For example, eight 10 MW plants could produce electricity at a cost between $0.098 and $0.119.

There is potential here, but the costs have to come down more to bring electricity from OTEC to a price to make hydrogen production economically attractive. Remember, we need to transport this hydrogen from the point of generation by ocean going tanker and distribute it by truck or rail tanker (or pipeline) to retail points.

Another potential source of electricity for hydrogen production is wave and tidal motion. To supply electricity for a power grid, the waves and tides must be close to populated shore lines. Wave motion can be used anywhere for hydrogen production, not just where is occurs close to populated shore lines. The same is true for tidal action in remote regions of the planet. The picture below, from New Scientist, shows a SeaGen tidal electricity generator, made by Sea Generation Ltd, in the tidal currents at Strangford Lough in Northern Ireland. Sea Generation is a division of privately held Marine Current Turbine Ltd.

Generation costs for electricity from capital costs alone will be about $0.07 per kWh for a 25 year depreciation. There will be additional unspecified maintenance and operation costs.

Wave action can also be used to generate electricity. The picture below (from New Scientist) shows a wave operated electrical power generator in a generation farm off the north coast of Portugal.

These generators are made by privately held Pelamis Wave Power Ltd. Each generator is a 150-meter-long steel jointed structure, which flexes to drive hydraulic generators and produce 750 kilowatts of power. The company claims electricity generation a competitive costs, but provides no specifics.

The reasons I selected these examples as potential hydrogen generation power sources are:

1. Potential for a lower electricity price point;

2. Electricity generated with plentiful raw material (water) present to produce hydrogen; and

3. With OTEC, the potential for additional revenue from side products.

Battery Costs vs. Fuel Cell Costs

The implications from currently available information are that the costs and durability will be similar. The current objective for Toyota is to have a price premium for hybrids less than the current price premium for a hybrid. The latest generation fuel cell engine is about the same size as a typical 4-cylinder ICE engine and contains about 30 grams of platinum. This is down from the previous generation fuel cell stack which was more than twice the size and contained 80 grams of platinum. The costs just for the platinum alone have been reduced from more than $4,000 in the previous

generation to less than $1,500 in the current one. The final fuel cell structure is expected to use only 10 grams of platinum, the same amount as a typical catalytic converter today.

The dramatic change from the previous generation hydrogen fuel cell stack power system to the current generation is seen in the following picture from AutoBlogGreen.com, showing the latest fuel cell drive system on the left next to the drive system used in the past few years in the Chevy Equinox test vehicles that have been driven by volunteers in California, Washington, DC and New York. The power, range and performance of the two systems are the same. The horsepower rating is the equivalent of a current four-cylinder ICE.

Transportation of Fuel and Wholesale Distribution

The technology for distribution by tanker truck and railway car exists today. You can not spend a few hours on any interstate highway near a population center without seeing several pressurized gas tank transports sharing the roadway with you. Pipeline distribution for pressurized hydrogen gas may require different features than currently use for natural gas, but there is no reason to believe that the engineering and construction would present any more challenges or costs. Currently, there is no data reflecting transportation and wholesale distribution impediments to scaling up the use of hydrogen to higher volumes.

Retail Distribution

The cost to build a new gasoline station has been estimated to be in the $250,000 to $450,000, with the largest variable being land cost, using estimates obtained from national average costs at RS Means Cost Works. Obviously, where land costs are extremely dear, near the center of major cities, for example, the cost to build a gasoline station could be much higher, up to $1,000,000 or more.

The cost of building the first 32 hydrogen refueling stations in Southern California has been quoted as $32 million. As high as this cost projection is, it is less than the current cost for a hydrogen refueling pump in Los Angeles, according to Phil Baxley, President of Shell Hydrogen, quoted in the Ohnsman article. He said currently the cost is from $1 million to $5 million per pump, depending on capacity. Even the lower quoted cost, averaging $1 million each for 32 stations, seems to be more costly than all but the most expensive gasoline stations. However, there are three factors related to hydrogen refueling stations that mean this apparent current cost difference may decrease or even be reversed. These are:

1. externality cost exposures for gas stations;

2. lower costs for hydrogen stations in the future through economies of scale; and

3. lower costs to add hydrogen to existing gas stations than to build new.

There are major externality exposures for petroleum based fueling stations. The biggest exposure pertains to future liabilities for soil and ground water contamination by petroleum products and fuel additives. When these externalities are realized, they can be more than the original construction cost (even adjusted for inflation) and occasionally are many millions of dollars. Hydrogen refueling stations do not have these environmental cost exposures.

When the initial costs and the externalities are considered, the refueling stations for hydrogen have an original construction cost of the same order as petroleum fuel stations. Hydrogen refueling stations may decrease in construction costs from the estimates for the first 32 stations in Southern California when many hundreds are constructed per year. If hydrogen were to become ubiquitous, there might be a few thousand new stations per year for a couple of years. A more likely progression would be the modification of existing gas stations to also offer hydrogen refueling facilities at a fraction of the cost of building new stations.

Other countries have more advanced plans for infrastructure development.Both Japan and Germany are working to build large scale distribution networks, with over 1,000 stations on line for each county in five years.

Safety

To start with, we must recognize that hydrogen would not be replacing something that did not have an extremely high fire and explosion hazard. We have managed to live with the risks of gasoline for more than a century, with the material being stored in thin walled tanks that can easily rupture.

Hydrogen, a pressurized gas, would be stored in thick walled, virtually indestructible tanks. Pressurized gases are handled in such containers in a variety of industrial environments today and have been for most of the past 100 years. There are few examples of these tanks being breached. The risks have been associated with the pressure reduction valves (regulating the controlled release of the gas) being broken by impact damage. The major risk associated with using hydrogen will be the exposure to the fuel lines being damaged and allowing the tanks to lose pressure rapidly, turning them into jet propelled missiles.

The pressurized gas tank as a missile is the major safety hazard. It is not insignificant, but should not be an insurmountable problem.

Conclusion

There are still a lot of questions to be answered. But one thing is clear: hydrogen powered cars are not dead. In congested metropolitan areas where electrical costs are high, hydrogen may become widely utilized. The further advantage of much longer travel ranges may also give hydrogen an additional edge over plug in alternatives.

It is too early to make investment decisions trying to select eventual winners. It is not wise to assume there will not be a viable hydrogen car and hydrogen distribution systems during the next decade.

John Lounsbury, CFP, PhD is a financial planner in Clayton, NC. He has extensive experience in computer technology research and development both as an engineer/scientist and in corporate management with academic degrees in physical science. He is a regular contributor to Real Money at TheStreet.com and to Seeking Alpha. Dr. Lounsbury also has his own professional blog, PiedmontHudson. His articles are widely circulated on the internet.

Hurray, Hydrogen is 5 years away….again….still…always. Wake me up when it’s here and ready to be rolled out.

John, OTEC and wave power are not the best candidates for cheap sources of renewable power to produce Hydrogen. The best candidate is wind, when it reaches high levels of penetration on the continental grid. This will produce excess power when the wind is strong and demand is low, and this excess power can be converted into hydrogen, which can later be used for fuel when it is needed.

Even at about 20% penetration, there have been times when European energy prices have fallen to (and even below) 0 when the wind is strong at night. Given storage for hydrogen (one option would be to mix it into the natural gas pipeline system at low concentrations – this would not require new infrastructure, but would mean that it could only be burned with natural gas, not used in HFCVs), much excess power could be put to use, and cheap electricity would be available to produce hydrogen.

Unlike OTEC and wave power, no technological advances are needed.

Blake – – –

Thanks for the comment. I’ll rest my case with the two paragraphs in the conclusion. To try to be a little lighthearted, I would just comment that those who don’t keep their eye on what might be coming up on the horizon sometimes find that they are run over by what they didn’t watch before they wake up from their nap.

Fuel cells have missed most of their window of opportunity in the automotive industry. Battery electric cars with 100 mile range, charged at home, will take the market share. The niche for fuel cells will be as range entenders for battery electric cars. Perhaps portable fuel cell solutions which are installed when a long trip is desired and then removed for daily commuting.

Tom – – –

You are very correct. I should have mentioned the use of excess power from sources that are variable in output (wind, solar PV, solar thermal)to make hydrogen to store the energy that would otherwise be wasted. Of course, there are competing storage mechanisms (batteries, flywheel, pumped hydro), so the economics of which is the most efficient storage/end use combination is a complex study in and of itself. John Peterson might have more to add to this.

There are two reasons I focused on oceanographic sources of power. (1) It is not widely discussed; and (2) the source of power and the source of water are combined at the same location minimizing grid infrastructure dependancies.

Fuel cells have been ‘less than a decade way’ since the early 1960s. It is the football to Charlie Brown. He falls for it over and over and over.

Fool me once shame on you. Fool me twice, shame on me. Fool me for 50 years, you have a well funded PR machine.

It would be “not wise” to assume that _this_ time it really will happen.

The cheapest source of H2 is currently from natural gas, making it (from this source) a non-renewable energy and CO2 producer.

Batteries are here now, and they work. Any car company that wants to make a real electric product in the next decade (or longer), will be making PHEV, BEV, or EREV, not a FCEV.

John —

Thanks for the in-depth article. As Patrick mentioned, most hydrogen today is made from natural gas and will be for some time to come. (Most electricity in the CA is from natural gas, too.) H2 produced from natural gas and used in a fuel cell vehicle reduces GHGs by about 50%.

Methane is a great source of H2 and we’re already seeing installations using H2 from onion mash, old beer, pulp processing, landfills and soon from sewage.

You also mention distribution. Many of the newer stations make their fuel onsite, eliminating the need for distribution. Hydrogen is, however, a common industrial gas used in refining gasoline, processing food, manufacturing consumer products (like toothpaste), making electronics and in pharmaceuticals. Hydrogen production, distribution and use aren’t new. What’s new is dispensing it into a vehicle and selling it as a retail product.

http://www.cafcp.org has information about the progress of vehicles and stations in California.

Great article, John.

Most hydrogen will be made initially from natural gas, just as much electricity is made by burning natural gas. It turns out that making hydrogen from natural gas (at the fueling station, for example) is more efficient than making electricity from natural gas. The net “well-to-wheels” efficiency of hydrogen from natural gas in a fuel cell electric vehicle is approximately 22% to 48% more efficient than using natural gas to generate electricity for a battery EV. [for details, see http://www.h2gen.com/Uploads/file/Battery_vs_FuelCell_EVs.pdf%5D