John Petersen

In late October I gave a keynote presentation at Batteries 2012, one of the largest lithium-ion battery conferences in the world. During the conference, I was buttonholed for a couple hours by the chairman’s global strategy team for one of the top three lithium-ion battery manufacturers in the world. They started by explaining that their Global 100 company is abandoning the plug-in vehicle market to focus on sensible applications where it can earn a reasonable margin. Then they started drilling down with a series of detailed and probing questions about whether any of the principal lead-acid battery markets might be an attractive opportunity for a company with their size, scale and stature.

While it may strike some of my readers as heresy, I told them that the lead-acid battery sector’s biggest vulnerability was in the rapidly evolving micro-hybrid market where industry leaders Johnson Controls (JCI) and Exide Technologies (XIDE) were focusing on the battery products they wanted to sell instead of the battery solutions their customers needed. After all, if legacy industry leaders won’t respond to changing customer needs, then it’s high time for new leaders that will respond.

The micro-hybrid revolution

Micro-hybrids are the most sensible automotive fuel efficiency technology imaginable. The primary goal of all micro-hybrids is simple: turn the engine off when it’s not powering the wheels. Last February, in a report titled “Every Last Drop: Micro‐ And Mild Hybrids Drive a Huge Market for Fuel‐Efficient Vehicles,” Lux Research segregated micro-hybrids into three broad classes:

- Light Micro-Hybrids, which reduce fuel consumption by about 5%, are typically compact and sub-compact cars that offer limited stop-start functionality and don’t have regenerative braking.

- Medium Micro-Hybrids, which reduce fuel consumption by about 10%, are sub-compact through full-size cars that offer greater stop-start functionality and may offer limited regenerative braking.

- Heavy Micro-Hybrids, which reduce fuel consumption by up to 15%, are usually mid- and full-size cars that offer the highest level of stop-start functionality, take full advantage of regenerative braking and offer a variety of advanced fuel economy innovations like high speed coasting.

While micro-hybrids are a new idea to most Americans, over half of new cars sold in Europe already use the technology and the U.S. is certain to follow suit over the next few years as automakers scramble to meet these short-term corporate average fuel economy standards.

| Passenger | Light | Combined |

|

| Model Year | Cars |

Trucks |

Fleet |

| (mpg) | (mpg) | (mpg) | |

| 2012 | 33.3 | 25.4 | 29.7 |

| 2013 | 34.2 | 26.0 | 30.5 |

| 2014 | 34.9 | 26.6 | 31.3 |

| 2015 | 36.2 | 27.5 | 32.6 |

| 2016 | 37.8 | 28.8 | 34.1 |

This graph from Lux shows how the global micro-hybrid market is expected to evolve over the next five years and grow from about five million units in 2011 to almost forty million units a year by 2017.

On a regional basis, Lux forecasts that:

- The European micro-hybrid market will grow from over 4 million units in 2011 to 12.6 million units by 2017.

- The North American micro-hybrid market will grow from a standstill in 2011 to over 8 million units by 2017.

- The Japanese micro-hybrid market will grow from about 400,000 units in 2011 to over 6 million units by 2017.

- The Chinese micro-hybrid market will grow from under 300,000 units in 2011 to 8.9 million units by 2017.

It will be the fastest technology revolution in automotive history. The reason for the speedy ramp is simple. Micro-hybrid technology won’t be a consumer option. Instead it will be standard fuel economy equipment.

The mechanical changes required to implement micro-hybrid technology are simple and cheap. One big challenge is that a micro-hybrid turns its engine off at every stop and turns it back on when the driver takes his foot off the brake. A second and even bigger challenge is that automakers want micro-hybrid systems to be transparent to their customers. The accessories have to keep working when the engine is off and they can’t stutter or fade when the engine restarts. It’s an immense challenge for the conventional lead-acid batteries we’ve all come to know and hate.

This graph from BMW shows the typical load on a micro-hybrid battery during an engine off event and the subsequent charge recovery cycle.

The block on the left (in red) represents the engine off period. The accessories draw 575 watts of power for a minute (34,500 watt-seconds) and the starter draws an additional 3,600 watts for one second. The car doesn’t start re-charging the battery (in green) until it’s done accelerating. Once the battery has recovered, the car draws 80 watts of power for another minute (4,800 watt seconds) before the next engine off event. In total, the duty cycle requires the battery to deliver and recover 42,300 watt seconds of power per cycle. With an average of one engine off event per mile, a micro-hybrid will demand 654,000 watt-seconds from its battery during a 16 mile commute where a conventional car would only need 6,000 watt-seconds.

The bottom line is that micro-hybrids require their batteries to do 100 times the work and if the batteries can’t stand the strain, the mechanical systems can’t deliver the fuel savings. Micro-hybrid systems that fail quickly because of feeble batteries are nothing more than green-wash. The automakers understand that problem and over the medium- to long-term they can’t settle for less. There’s always a bit of regulatory rubber when new technologies are being introduced and refined, but once a new technology becomes widespread the regulators get far more demanding.

Legacy manufacturers’ initial response

Last week I wrote an exclusive article for Seeking Alpha that explained the differences between the two principal classes of lead acid batteries. It described flooded lead acid batteries as “Lead-acid 1.0” and AGM batteries as “Lead-acid 2.0.” It further explained that the various types of enhanced flooded batteries are the equivalent of

Lead-acid 1.x while various types of enhanced AGM batteries are the equivalent of Lead-acid 2.x. Since the analogy resonated deeply with many readers who were previously confused about the issue, I’ve decided to continue using that classification system.

This graph from a presentation at the recent European Lead Battery Conference shows what happens to the dynamic charge acceptance of three different types of AGM batteries over one year of simulated service using the BMW micro-hybrid duty cycle. The basic AGM battery, Lead-acid 2.0, is the blue line on the bottom. An enhanced AGM battery with graphite paste additives, Lead-acid 2.x, is the red line in the middle. A second type of enhanced AGM battery with expanded graphite and activated carbon paste additives, Lead-acid 2.x.y, is the green line.

A brand new AGM battery that can accept a 50 amp charging current will take 72 seconds to recover the energy consumed during an engine off cycle. A one-year-old AGM battery that can only accept a 10 amp charging current will take 430 seconds to recover that energy. A micro-hybrid that can turn the engine off once a minute will always save more fuel than a micro-hybrid that can only turn the engine off once every seven minutes.

This graph is the main reason I told the lithium-ion battery manufacturer that the lead-acid battery industry was vulnerable in the micro-hybrid market. Instead of recognizing and accepting the reality that Lead-acid 1.x and 2.x will never be suitable for micro-hybrids, the industry leaders were stubbornly promoting improved versions of legacy products that can’t provide the performance the automakers must have. Since my meeting in October the dynamic has gotten significantly better and if it continues, my concerns over vulnerability will rapidly pass.

Legacy manufacturers’ evolving responses

The last two months have been a fascinating time as the two biggest legacy manufacturers started to back away from their earlier insistence that Lead-acid 1.x and 2.x would be ideal solutions for micro-hybrids.

The first legacy manufacturer to soften it’s position was Exide Technologies, which announced a strategic alliance with Maxwell Technologies (MXWL) in mid-November. The two companies plan to jointly develop and market integrated battery-ultracapacitor solutions for a wide array of transportation and industrial applications. While the details remain sketchy, it appears that the Maxwell-Exide alliance will offer a micro-hybrid solution that’s similar to a system launched by Maxwell and Continental AG in the fall of 2010. That system pairs an AGM battery from Continental with a 2,400 Farad ultracapacitor module from Maxwell. The combination is reportedly very good at avoiding voltage sags and accessory fade when the engine restarts, but it can’t address the biggest energy drain in a micro-hybrid; the 60-seconds of accessory use during an engine off interval. Since the Maxwell-Continental system only addresses the engine restart loads, the problems with rapidly declining dynamic charge acceptance in the AGM battery remain and so do the performance deterioration issues.

The second legacy manufacturer to significantly change its position was Johnson Controls which surprised many during last week’s “Strategic Review and 2013 Outlook Analyst Presentation.” In that presentation the president of JCI’s Power Solutions unit came right out and said that Lead-acid 1.x and 2.x were not adequate solutions for heavy micro-hybrids. He then went on to explain that JCI was planning to launch an integrated lead-acid and lithium-ion battery solution that would use a 12-volt lead-acid battery for the engine start load and a 42-volt lithium-ion battery for the accessory loads. Curiously, JCI continues to claim that Lead-acid 1.x and 2.x will be ideal solutions for light and medium micro-hybrids even though those vehicles just have a milder case of the battery problems that plague heavy micro-hybrids. I expect that position to evolve into something more reasonable over the next couple years.

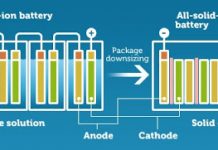

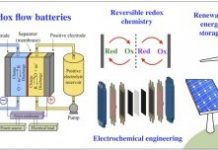

The emergence of Lead-acid 3.0

Over the last decade immense progress has been made in the development of an entirely new class of lead-acid battery that integrates components from conventional lead-acid batteries and supercapacitors into an entirely new class of device. These asymmetric lead-carbon capacitors, Lead-acid 3.0, use normal pasted lead-grids for their positive electrodes and sophisticated carbon electrode assemblies for their negative electrodes. One of these devices, the PbC battery from Axion Power International (AXPW.OB) has proven to be a very promising solution for the power demands of micro-hybrids. This graph from Axion’s recent presentation at the European Lead Battery Conference shows why.

While a top-quality AGM battery starts out with the ability to accept a 50 amp charging current but rapidly fades over the first year of service, the PbC is able to accept a 100 amp charging current for almost five years without degradation and its charge acceptance doesn’t fall into the 50 amp range for almost nine years. The PbC recently completed a three-year performance-testing regime at BMW, which has reportedly sent its results to a third-party for an independent peer review. The next logical step in the process will be fleet testing prior to a production decision. When BMW conducted fleet testing of AGM batteries for micro-hybrids in 2007, the work took six months. While testing of the PbC may take more time, it shouldn’t take much longer because there’s very little an OEM can learn in a car that it hasn’t already learned in the laboratory.

Three years ago the PbC was a promising dark horse contender in the battle for position in the micro-hybrid battery space, but it hadn’t proven its mettle in performance and validation testing by automakers. Today the principal validation and testing work has been completed and while there’s a chance that fleet testing will reveal issues that weren’t discovered in the testing laboratories, that possibility is remote. My inner optimist wants to believe fleet testing can be completed in time for a 2014 model year design win next September. My inner pragmatist thinks a design win for the 2015 model year is more likely.

The next likely steps

The recent actions of Exide and JCI evidence a dawning realization that the micro-hybrid revolution will require more robust and more costly energy storage systems than automakers are used to buying. In JCI’s strategic review Mr. Molinaroli spent a good deal of time discussing the economic constraints on battery manufacturers. He said that while consumers were willing to accept a three-year payback on fuel economy systems, they weren’t willing to pay more. That suggests that automakers will strive to reach the following price targets for the battery systems in the three classes of micro-hybrids assuming fuel savings of 5%, 10% and 15%, and gasoline prices of $3.50 and $4.00 a gallon.

| Vehicle Class |

Savings |

$3.50 Gas |

$4.00 gas |

| Light Micro-hybrid | 5% | $210 | $240 |

| Medium Micro-hybrid | 10% | $420 | $480 |

| Heavy Micro-hybrid | 15% | $630 | $720 |

These are challenging price points, particularly when you get into systems that integrate two different types of energy storage devices and have to design sophisticated control electronics to accommodate the differences.

In all probability, Lead-acid 1.x and 2.x will be the only viable solutions for light-micro hybrids because the price targets are so low. The most likely solution will be dual battery system that uses a flooded battery for the engine start loads and an AGM battery for the accessory loads. The probability that a single battery system will survive over the long term is remote.

The medium micro-hybrid space presents a significant challenge for both the automakers and the battery industry. The dual battery systems that are likely to dominate the light micro-hybrid space won’t be adequate for the heavier demands of medium micro-hybrids. In particular, the rapidly declining charge acceptance of Lead-acid 1.x and 2.x will preclude extensive use of regenerative braking which depends on the battery’s ability to rapidly accept a regenerative charge during a short braking interval. While the capabilities of integrated battery-ultracapacitor systems are better than dual battery systems alone, the medium micro-hybrid niche is a natural target for the PbC once it finishes the performance and validation testing process.

The heavy micro-hybrid space is shaping up as a battleground between the dual chemistry systems proposed by JCI and Axion’s PbC. Lithium-ion batteries have the high charge acceptance needed for large accessory loads and they can handle aggressive regenerative braking loads but they’re expensive and very complex, particularly when you get into higher voltage batteries that require extensive changes to existing automotive control and accessory systems. In the heavy micro-hybrid market, I believe the PbC will enjoy a significant cost advantage.

Who benefits and when?

I love talking about the intricacies of battery technologies but understand full well that the primary question in the minds of investors is “who benefits and when?” The short sweet answer is every company in the sector.

Automakers are building micro-hybrids today and they want to build more aggressive micro-hybrids next year and the year after that. The only battery manufacturers who have the near-term ability to satisfy the automakers needs for better energy storage systems are the legacy leaders JCI and Exide. Both of these companies can expect significant increases in their per vehicle revenues and margins over the next few years. The rapid revenue and margin gains already baked into the business cake but they’re not yet reflected in the stock prices. No matter how the micro-hybrid battery market develops, these legacy leaders will remain leaders for years to come.

Another near-term beneficiary is Maxwell which should see its ultracapacitor sales ramp rapidly as automakers strive to minimize voltage sags and accessory fade during engine restart cycles. The integrated AGM battery and ultracapacitor combination is not an ideal long-term solution to the dynamic charge acceptance problems that plague Lead-acid 1.x and 2.x, but it is a very good solution for automakers that want their micro-hybrid systems to remain transparent to drivers.

In the medium- to long-term, I believe Axion’s PbC presents the greatest upside potential and the greatest risk. OEM testing has proven that the PbC offers extraordinary performance in the micro-hybrid duty cycle. While the test results have been great, the critical steps of fleet testing and contract negotiation haven’t started yet, so the PbC is still a year or two away from a formal design win. First generation PbC batteries are relatively expensive, but the materials used in a PbC battery are no more costly than the materials used in a conventional AGM battery. As Axion increases production from start-up volumes to credible commercial quantities, its opportunities for economies of scale and experience curve effects are tremendous. Over the longer term Axion wants to become a component supplier to the legacy leaders, rather than a competitor. While it will have to overcome a good deal of “not invented here” thinking, if the automakers demand the PbC’s performance, their battery suppliers will have no choice.

While pharmaceutical and biotech investors understand that stock values change rapidly when R&D stage companies advance from Phase II clinical testing to Phase III efficacy trials, unique new battery technologies are rare enough that the market hasn’t quite come to grips with the striking differences between where the PbC technology was in 2009 and where it is today. The last three years have been a veritable PR drought because there isn’t much to talk about while OEM testing is being conducted. That dynamic will change significantly over the next year as first tier OEMs and battery users in automotive, railroad, heavy trucking and stationary applications launch a series of large scale demonstration projects as a prelude to rapid commercialization.

Disclosure: Author is a former director of Axion Power International (AXPW.OB) and holds a substantial long position in its common stock.

John

Interesting conversation!

Could Axion work with a dozen smaller LAB manufacturers?

Would the OEMs go for this kind of setup?

THX

BTW A minor chart problem.

Heavy hybrid savings should be 15% not 10

The original plan was to start with two or three partners in each market region (NA, Europe, Asia) and keep supply relationships close until the technology is established and demand reaches a point where additional partners are needed. Because of the way patents work we might also see vertical division in a region where Partners A and B do automotive while Partners C and D focus on rail and trucking. As long as the OEMs get their needs satisfied with good service, I suspect they’d rather deal with a local Axion partner than Axion at distance.