John Petersen

Last week Lux Research published a report titled “Micro-hybrids: On the Road to Hybrid Vehicle Dominance” that forecasts micro-hybrid vehicle sales of three million units this year increasing to 34 million units annually by mid-decade. Lux sent me a courtesy copy of their report and will host a webinar to discuss their findings on November 16th.

While I’m very excited about Lux’s conclusions respecting micro-hybrid implementation rates, it’s critical for investors to understand that batteries for micro-hybrids will merely be upgrades of batteries that would have been sold in any event. Therefore, the benefit to battery manufacturers will be limited to the difference between the price of stop-start batteries and the price of conventional batteries they’ll replace. So while Lux valued the market at $2.7 billion annually, the incremental revenue to the energy storage sector will be a good deal lower.

Micro-hybrids, or more accurately “stop-start idle elimination systems,” are baby steps in vehicle electrification. Stop-start systems don’t provide any drive power to the wheels and their only goal is to reduce fuel consumption by turning the engine off when the car isn’t moving. It’s a thoroughly sensible idea, but one that’s extremely hard on batteries because instead of starting the engine twice in an average day, an optimal stop-start system will start the engine an average of once per mile while powering all accessories during engine-off intervals.

The following graph is a scale representation of battery loads in a conventional vehicle and in a vehicle equipped with a stop-start system. The conventional vehicle cycle is simply a 1-second starter load of 300 Amps (blue spike) before the alternator kicks in to recharge the battery. The stop-start vehicle cycle, in comparison, has a 60-second accessory load of 50 Amps (pink block) with a one-second starter load of 250 Amps (red spike) at the end. While we naturally tend to think of engine restart as the main issue, the truly serious problem for stop-start systems is the accessory loads that account for a whopping 92% of total energy demand.

In a typical year, the battery in a conventional vehicle will need to start the engine about 730 times and deliver about 262,800 watt seconds of energy to the starter. In contrast, the battery in a vehicle equipped with a fully optimized stop-start system will need to start the engine 12,500 times and deliver 487.5 million watt seconds of energy. In other words, the batteries for a fully optimized stop-start system will need to provide 17.1 times the cycling and 1,855 times the energy delivery. It’s a very tall order.

The harsh reality is that currently available lead-acid batteries are not robust enough to stand up to the demands of stop-start. Therefore, to avoid irreparable battery damage, all stop-start vehicles have control electronics that monitor the battery’s state of charge and disable the stop-start system until the battery recovers. On new vehicles with new batteries the stop-start systems work beautifully. As the batteries age and charging intervals get longer, the frequency of stop-start events plummets. In many cases the stop-start system simply doesn’t work after a few months. This is a serious problem for the automakers that requires a serious solution.

The first alternatives the automakers tried to improve the performance of stop-start systems included upgrading from flooded batteries to AGM batteries, and/or adding a second battery. While AGM batteries perform better than flooded batteries and two batteries perform better than one, the workarounds don’t solve the fundamental problem.

In late September, Continental AG and Maxwell Technologies (MXWL) announced a design win for a dual-device system that will couple a 3,020 watt supercapacitor module with an AGM battery for diesel-powered cars from PSA-Peugeot-Citroën. While Peugeot-Citroën, Continental and Maxwell believe the supercapacitor will make a big difference in the system’s ability to handle the heavier starting loads of diesel engines, the 8,784 watt seconds of energy from the supercapacitor won’t begin to solve the accessory load issue.

The bottom line is the automobile industry needs better energy storage solutions if stop-start idle elimination is to achieve its full fuel savings and emissions reduction potential.

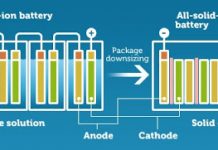

The Department of Energy believes the most promising short-term alternatives are third-generation devices that combine carbon nanotechnology and lead-acid chemistry in a monoblock battery. The two leading contenders, which both received awards under the DOE’s ARRA Battery Manufacturing Grant program, are:

- The Ultrabattery from CSIRO, Furukawa and East Penn Manufacturing, a flooded device that uses a split-electrode design to replace half of each lead-based negative electrode with a carbon electrode, resulting in a 75% – 25% battery/supercapacitor hybrid; and

- The PbC battery from Axion Power International (AXPW.OB) and Exide Technologies (XIDE), an AGM device that replaces all of the lead-based negative electrodes with carbon electrode assemblies, resulting in a 50% – 50% battery/supercapacitor hybrid.

The Ultrabattery and the PbC are both in the final development stages. While their developers have been fairly tight-lipped about performance, data is starting to emerge. Last February, a Journal of Power Sources article (Volume 295, Issue 4, Page 1243) included the following graph that compares the performance of a flooded lead-acid battery, an enhanced flooded battery [ISS] and an Ultrabattery in a simulated stop-start environment.

At this year’s European Lead Battery Conference in Istanbul, Axion and BMW published updated versions of the following graphs that compare the PbC battery and a high quality AGM battery over a 40,000-cycle test. The graph on the left is the AGM battery and the downward curving blue line represents the charge acceptance rate, which declines rapidly from an initial value of 70 Amps and eventually stabilizes around 20 Amps. The upward curving black line represents the time required to regain an optimal state of charge which begins at about 30 seconds and eventually stabilizes in the 120 second range. The graph on the right is the PbC battery, which maintains a stable charge acceptance rate of 100 Amps and a stable recovery time of 30 seconds for the entire test period, which approximates a five-year service life.

The Ultrabattery and the PbC are both properly classified as late-stage development projects. The technologies have performed very well in demonstration and testing, but their developers are working on industrial and production engineering issues and will need to expand production c

apacity before they can satisfy more than a small fraction of the automotive market. Since both technologies are generational improvements on established lead-acid chemistry, they should enjoy significant speed and cost advantages during the commercial introduction phase because of their ability to leverage supply chains, existing production facilities and global distribution chains that already exist for their flooded and AGM cousins.

Based on interviews with automakers about their current stop-start implementation plans, Lux concluded that enhanced flooded batteries would account for over $1 billion in annual sales by 2015 (39% market share); AGM batteries would account for another $1.6 billion in annual sales (59% market share); and dual-device systems like the Continental-Maxwell battery-supercapacitor product would account for $55 million in annual sales (2% market share). While Lux acknowledged the Ultrabattery and PbC as emerging technologies that could be contenders, it was apparently unwilling to estimate future market penetration rates for devices that aren’t available yet.

On the topic of investment opportunities in the stop-start market, the Lux report said, “Unlike the lithium-ion battery space, which sports a number of early-stage start-ups, the micro-hybrid storage market supports few startups outside of Swedish firm Effpower. Outside of the giants like Johnson Controls, Exide Battery, and GS Yuasa, most of the investment/acquisition plays are public companies like Maxwell Technologies [$414 million market capitalization] and Axion Power [$48.5 million market capitalization]. Of the two, Maxwell is the surer bet right now, with revenues over $100 million and a major automotive contract already in place. However, don’t count out Axion completely – although its technology is on the expensive side today, it has a large war chest, a strong partner in Exide, and compelling opportunities in distributed storage and uninterruptible power supply (UPS) systems even if the micro-hybrid market doesn’t pan out.” [My additions]

The flooded and AGM batteries automakers are currently using for stop-start systems are woefully inadequate for the job, with and without supercapacitor modules. Since regulations concerning fuel economy and CO2 emissions are the driving force behind the rapid global implementation of stop-start technology, I think it’s very unlikely that governments will let automakers circumvent the rules by using conventional flooded and AGM batteries that leave the stop-start systems inoperable within a few months. As reports from stop-start vehicle owners like my friend Graham who says “I can’t remember the last time the engine in my Mini turned itself off during a drive,” become more common, revised regulations that focus on lifetime performance instead of new vehicle performance are almost certain. At that point the industry will be forced to shift over to more robust batteries for stop-start vehicles even if they are $100 to $150 more expensive.

Disclosure: Author is a former director of Axion Power International (AXPW.OB) and holds a substantial long position in its common stock.